65U2X6.2G Extrusion Blow Molding Machine

Introduction

| 65U2X6.2G Extrusion Blow Molding Machine | Example | Milk bottle 220 ml, 17 g |

| Twin Station 6 Cavities Blow Moulder up to 220 ml | Output | 25000/hr,60988 /day, 21.3 million/year |

75U+S2X1.10F bottle extrusion blow moulding machine is specialized in producing middle-sized plastic containers like cosmetic bottles, detergent bottles, etc. With double mold bases, one to eight die heads for choice, sliding rail for moving molds, and many other excellent working performances, this machine boasts safe operation and high production efficiency. Besides, a labeling machine is available to co-work with this bottle extrusion blow moulding machine, such as to label the plastic products once after they are formed. In this way, an entire automatic production line cuts down production costs and saves production circle.

General Features

- 1. The screw diameter is 65mm and die head distance is 70 mm

- 2. With six die heads and double layer, 65U2X6.2G plastic blowing machinery is of high production output for single layer plastic products.

- 3. With scissor toggle clamping system, the rigidity mold clamping features larger and more uniform force than the conventional extrusion blow molding machine.

- 4. High accuracy linear guide rail facilitates fast moving speed and stable production.

- 5. The power consumption is decreased due to the adoption of double pump and proportional flow valve.

- 6. Automatic lubrication system is applied.

- 7. 65U2X6.2G plastic blowing machinery is configured with thickness control system.

- 8. Designed according to ergonomics, this extrusion blow molding machine utilizes user-friendly touch screen for operation. Besides, industrial PC networking is applied. This control system can receive signals through WIFI or 3G.

- 9. Maximum blow volume is 220 ml.

- 10. It is suitable for production of milk bottles, glue bottle and drug bottles. Available plastic materials are PE, PP, etc.

Technical Data of 65U2X6.2G Extrusion Blow Molding Machine

1. General Features

| Carriage Horizontal Shuttle Stroke | mm | 500 |

| Dry Cycle | sec | 4" |

| Clamp Force | kN | 47 |

Pressure of Hydraulic System |

Mpa |

14 |

Pressure of Pneumatic System |

Mpa |

0.6-0.8 |

Pressure of Cooling System |

Mpa |

0.2-0.3 |

| Air Consumption (Estimated) | m3 / hr | 5 |

| Minimum Pressure for Cooling Water to Machine | Mpa | 0.2 |

| Power of Pump Motor for Hydraulic Movements | kW | 7.5 |

| Power of Servo Pump Motor (if Needed) | kW | 3.75 |

| Power of Die Head Heating | kW | 6.5 |

| Power of Knife | kW | 2 |

| Total Power Installed (Estimated, Maximum) | kW | 40(43.75) |

2. Extruders

| Screw Diameter | mm | 65 |

| Extruder Rotating Speed | / | 20~71 |

| Power of Electric Motor | kW | 15 |

| Power of Barrel Heating | kW | 3 |

| Max. Throughput = PE | kg/h | 70 |

| Max. Throughput = PP | kg/h | 50 |

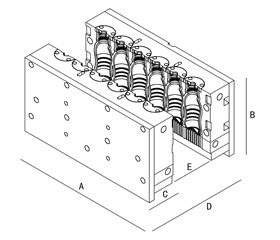

3. Mould Dimensions

| Maximum Width | A | mm | 380 |  |

| Maximum Length | B | mm | 300 | |

| Minimum Depth | C | mm | 94 | |

| Clamp Open Max. Daylight | D | mm | 337 | |

| Open Stroke | E | mm | 160 | |

| Max Weight of Mould | kg | 100 |

4. Production Possibilities

| Cavities | 6 | |

| Max. Center Distance | mm | 70 |

| Max. Container Width | mm | 60 |

| Max. Container Height | mm | 180 |

| Max. Container Depth | mm | 78.5 |

| Container Capacity (Estimated) | lt | 220 |

5. Machine Dimensions

| Maximum Width | mm | 3450(2150) |

| Maximum Length | mm | 3230 |

| Maximum Height | mm | 2400 |

| Total Weight | kg | 7600 |

We provide one year equipment warranty, free installation for domestic market, for charging debugging in oversea market and all-life services. Parts of our extrusion blow molding machines are free replacement for one year except for the rapid wear parts

English

English Português

Português Français

Français 08_155_large

08_155_large 43572_1

43572_1 200712~1

200712~1 BATH-P~1

BATH-P~1 hotel-shower-gel

hotel-shower-gel medicine

medicine toys

toys