Product » Blow Moulding Machine » PE PP PVC EVA EVOH Blow Molding Machine » U-Blow Moulding Machine » 65U2X1.5F 5L Blow Molding Machine

65U2X1.5F 5L Bottle Blow Molding Machines

Introduction

| 65U2X1.5F 5L Bottle Blow Molding Machines | Example | Oil Bottle 4L, 210 g |

| Twin Station Single Cavity Blow Moulder up to 4L | Output | 180/hr, 4300 /day, 1.5 million/year |

As dedicated plastic container blow moulding device suppler, Lanteky can produce automatic blow molding machine according to your requirements. Our machinery is designed and built with strict quality standards. It is applicable for production of food or beverage package bottles as well as many industry-use containers.

General Features of 65U2X1.5F 5L Bottle Blow Molding Machines

- 1. The screw diameter is 65 mm.

- 2. It is equipped with single die head, double station and single layer. Another optional set is to be configured with double die head, four- die head、multi-layer and view stripe.

- 3. Scissors toggle clamping system endows the machine with high rigidity molding clamping and larger as well as more uniform clamping force than other machines.

- 4. 65U2X1.5F 5L bottle blow molding machines apply high accuracy linear guide rail to increase moving speed and production stability.

- 5. The power consumption can be decreased with the adoption of double pump and proportional flow valve.

- 6. It is configured with thickness control system and works with integration of various take-out concepts.

- 7. Intelligent industrial PC networking is applied (both WIFI and 3G are applicable) in 65U2X1.5F 5L bottle blow molding machines. Besides, the touch screen makes operation more user-friendly.

- 8. In-mould labeling is available.

- 9. Maximum blow volume is 4 L. Available plastic materials for this machine are PE, PP, PS, PC and PVC. Products by this plastic container blow moulding device are lubrication bottles, cleaning stuff bottles, toys, auto parts, etc.

Technical Data of 65U2X1.5F 5L Bottle Blow Molding Machines

1. General Features

| Carriage Horizontal Shuttle Stroke | mm | 500 |

| Dry Cycle | sec | 4.3" |

| Clamp Force | kN | 78 |

Pressure of Hydraulic System |

Mpa |

14 |

Pressure of Pneumatic System |

Mpa |

0.6-0.8 |

Pressure of Cooling System |

Mpa |

0.2-0.3 |

| Air Consumption (Estimated) | m3 / hr | 5 |

| Minimum Pressure for Cooling Water to Machine | Mpa | 0.2 |

| Power of Pump Motor for Hydraulic Movements | kW | 7.5 |

| Power of Servo Pump Motor (if Needed) | kW | (5.5) |

| Power of Die Head Heating | kW | 5 |

| Power of Knife | kW | 2 |

| Total Power Installed (Estimated, Maximum) | kW | 38.5(44) |

2. Extruders

| Screw Diameter | mm | 65 |

| Extruder Rotating Speed | / | 20~67 |

| Power of Electric Motor | kW | 15 |

| Power of Barrel Heating | kW | 9 |

| Max. Throughput = PE | kg/h | 60 |

| Max. Throughput = PP | kg/h | 40 |

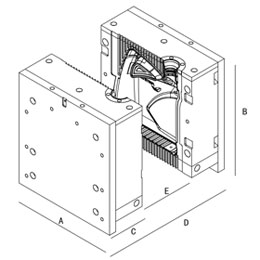

3. Mould Dimensions

| Maximum Width | A | mm | 300 |  |

| Maximum Length | B | mm | 365 | |

| Minimum Depth | C | mm | 100 | |

| Clamp Open Max. Daylight | D | mm | 450 | |

| Open Stroke | E | mm | 250 | |

| Max Weight of Mould | kg | 100 |

4. Production Possibilities

| Cavities | 1 | 2 | 3 | 4 | |

| Max Center Distance | mm | / | 120/150 | 85/100 | 65/70/85/100 |

| Max Container Width | mm | 280 | 110/140 | 75/90 | 55/60/75/90 |

| Max Container Height | mm | 245 | 245 | 245 | 245 |

| Max Container Depth | mm | 135 | 135 | 135 | 135 |

| Container Capacity (Estimated) |

L | 5 | 2 | 1 | 0.5 |

5. Machine Dimensions

| Maximum Width | mm | 3600/(2150) |

| Maximum Length | mm | 3800 |

| Maximum Height | mm | 2450 |

| Total Weight | kg | 8000 |

One year warranty is provided to 65U2X1.5F 5L bottle blow molding machines. We offer free installation service to domestic clients. Equipment parts are offered with free replacement during the warranty time (excluding the rapid wear parts).

Related Product

English

English Português

Português Français

Français

2SM-4-large

2SM-4-large BLL4-large

BLL4-large