75-55-25U+S2X1.10F Double Layer Blow Molding Machine

Description

75-55-25U+S2X1.10F double layer blow molding machine is specialized in production of double layer plastic products like lubrication bottles, cleaning stuff bottles, toys, auto pats, etc. It is equipped with twin station blow mould whose volume ranges from 5 L to 10 L. If the 5000 ml and 250 g oil bottle is produced by this machine, 220 this kind of bottles can come into being in one hour, 5400 in one day, and 1.89 million one year. As dedicated automatic blow moulding device manufacturer, we supply a series of molding machines as well as molds, auxiliary equipments, etc.

General Features

- 1. The screw diameter is 75 mm, 55 mm or 25 mm.

- 2. This double layer blow molding machine is configured with single die head and double station.

- 3. With scissors toggle clamping system, it features high rigidity mold claming, and the clamping force is far beyond that of molding machines made by many other manufacturers.

- 4. High accuracy linear guide rail endows it with fast moving speed and stable production.

- 5. Thanks to the double pump and proportional flow valve, the power consumption is greatly decreased.

- 6. Automatic lubrication system and thickness control system are applied.

- 7. The double layer blow molding machine adopts integration of various take-out system.

- 8. To make operation more user-friendly, quality touch screen is utilized. Besides, industrial PC networking supports controlling through WIFI or 3G.

- 9. In-mould labeling is available.

- 10. Applicable plastic materials to form bottles are PE, PP, PS, PC, PVC, etc.

Technical Data of 75-55-25U+S2X1.10F Double Layer Blow Molding Machine

1. General Features

| Carriage Horizontal Shuttle Stroke |

mm |

650 |

| Dry Cycle |

sec |

4.8" |

| Clamp Force |

kN |

127 |

| Pressure of Hydraulic System |

Mpa |

14 |

| Pressure of Pneumatic System |

Mpa |

0.6-0.8 |

| Pressure of Cooling System |

Mpa |

0.2-0.3 |

| Air Consumption (Estimated) |

m3 / hr |

5 |

| Minimum Pressure for Cooling Water to Machine |

Mpa |

0.2 |

| Power of Pump Motor for Hydraulic Movements |

kW |

15 |

| Power of Servo Pump Motor (if Needed) |

kW |

(5.5) |

| Power of Die Head Heating |

kW |

8 |

| Power of Knife |

kW |

2 |

| Total Power Installed (Estimated, Maximum) |

kW |

63.7 |

2. Extruders

| Screw Diameter |

mm |

75/25 |

| Extruder Rotating Speed |

/ |

20~50/2-25 |

| Power of Electric Motor |

kW |

22/2.2 |

| Power of Barrel Heating |

kW |

12.5/2 |

| Max. Throughput = PE |

kg/h |

120&2.2 |

| Max. Throughput = PP |

kg/h |

90 |

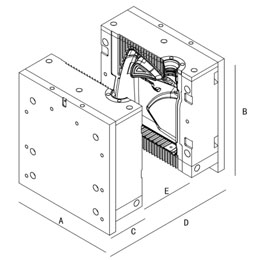

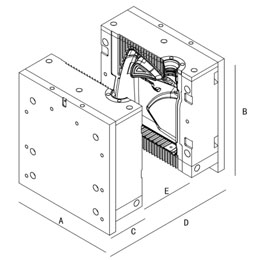

3. Mould Dimensions

| Maximum Width |

A |

mm |

380 |

|

| Maximum Length |

B |

mm |

440 |

| Minimum Depth |

C |

mm |

115 |

| Clamp Open Max. Daylight |

D |

mm |

580 |

| Open Stroke |

E |

mm |

230 |

| Max Weight of Mould |

|

kg |

100 |

4. Production Possibilities

| Cavities |

|

1 |

| Max. Center Distance |

mm |

/ |

| Max. Container Width |

mm |

280 |

| Max. Container Height |

mm |

320 |

| Max. Container Depth |

mm |

190 |

| Container Capacity (Estimated) |

L |

10 |

5. Machine Dimensions

| Maximum Width |

mm |

3150/(2200) |

| Maximum Length |

mm |

4340 |

| Maximum Height |

mm |

2600 |

| Total Weight |

kg |

9000 |

We provide one year equipment warranty, free installation for domestic market, for charging debugging in oversea market and all-life services. Equipment parts of 75-55-25U+S2X1.10F double layer blow molding machines are free replacement for one year except for the rapid wear parts.

Related Product

English

English Português

Português Français

Français