75-25U+S2X1.10F Container Extrusion Blow Molding Machine

Introduction

75-25U+S2X1.10F container extrusion blow molding machine is applicable for production of lubrication bottles, cleanings stuff bottles, toys, auto parts and many other plastic articles whose volume is below 10 L. Available plastic materials are PE, PP, PS, PC, PVC, etc. Guangdong Lanteky machinery is widely sold at home and abroad. We can customize machines according to clients’ requirements.

| 75-25U+S2X1.10G |

Example |

Oil Bottle 5000 ml, 250 g |

| Twin Station Blow Moulder up to 10L with View Stripe |

Output |

220/hr, 5400 /day, 1.89 million/year |

General Features of 75-25U+S2X1.10F Container Extrusion Blow Molding Machine

- 1. The screw diameter is 75 mm or 25 mm.

- 2. It is with single die head and double station.

- 3. Equipped with scissors toggle clamping system, it is of high rigidity mold clamping; besides, this Guangdong Lanteky machinery’s clamping force is far larger than machines produced by many other manufacturers.

- 4. High accuracy linear guide rail is applied to ensure fast moving speed and stable production.

- 5. This container extrusion blow molding machine consumes less power due to the adoption of double pump and proportional flow valve.

- 6. Automatic lubrication system and thickness control system are applied.

- 7. Touch screen is designed according to ergonomics. Besides, intelligent peripheral devices adopt the industrial PC networking (WIFI or 3G is available).

- 8. In-mould labeling is applicable.

Technical Data of 75-25U+S2X1.10F Container Extrusion Blow Molding Machine

1. General Features

| Carriage Horizontal Shuttle Stroke |

mm |

650 |

| Dry Cycle |

sec |

4.8" |

| Clamp Force |

kN |

127 |

| Pressure of Hydraulic System |

Mpa |

14 |

| Pressure of Pneumatic System |

Mpa |

0.6-0.8 |

| Pressure of Cooling System |

Mpa |

0.2-0.3 |

| Air Consumption (Estimated) |

m3 / hr |

5 |

| Minimum Pressure for Cooling Water to Machine |

Mpa |

0.2 |

| Power of Pump Motor for Hydraulic Movements |

kW |

15 |

| Power of Servo Pump Motor (if Needed) |

kW |

(5.5) |

| Power of Die Head Heating |

kW |

8 |

| Power of Knife |

kW |

2 |

| Total Power Installed (Estimated, Maximum) |

kW |

63.7 |

2. Extruders

| Screw Diameter |

mm |

75/25 |

| Extruder Rotating Speed |

/ |

20~50/2-25 |

| Power of Electric Motor |

kW |

22/2.2 |

| Power of Barrel Heating |

kW |

12.5/2 |

| Max. Throughput = PE |

kg/h |

120&2.2 |

| Max. Throughput = PP |

kg/h |

90 |

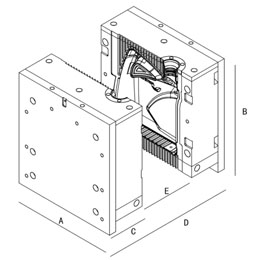

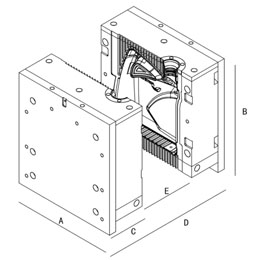

3. Mould Dimensions

| Maximum Width |

A |

mm |

380 |

|

| Maximum Length |

B |

mm |

440 |

| Minimum Depth |

C |

mm |

115 |

| Clamp Open Max. Daylight |

D |

mm |

580 |

| Open Stroke |

E |

mm |

230 |

| Max Weight of Mould |

|

kg |

100 |

4. Production Possibilities

| Cavities |

|

1 |

| Max. Center Distance |

mm |

/ |

| Max. Container Width |

mm |

280 |

| Max. Container Height |

mm |

320 |

| Max. Container Depth |

mm |

190 |

| Container Capacity (Estimated) |

L |

10 |

5. Machine Dimensions

| Maximum Width |

mm |

3150/(2200) |

| Maximum Length |

mm |

4340 |

| Maximum Height |

mm |

2600 |

| Total Weight |

kg |

9000 |

Each container extrusion blow molding machine is provided with one year equipment warranty. During this period, broken machine parts (not including the fast wear parts) can be replaced into the new ones. For domestic clients, we additionally offer installation service.

Related Product

English

English Português

Português Français

Français DRC5-large

DRC5-large HT10W30-5-large

HT10W30-5-large LLTU5-large

LLTU5-large MGO75W90-4-large

MGO75W90-4-large NATF-1-large

NATF-1-large NATF-4-large

NATF-4-large SYN10W40-1-large

SYN10W40-1-large