85U+S2X8.5G Bottle/Container Blowing Machinery

Introduction

85U+S2X8.5G automatic blow molding machines are suitable for producing hollow plastic articles under 0.5 L and made from PE, PP, EVA, ABS, PVC, TPU, Nylon and many other materials. Lanteky can also manufacture custom bottle/container blowing machinery for clients. Each 85U+S2X8.5G machine can produce 3300 bottles (250 ml, 17g/per bottle) per hour, and 79200 per day, 25 million per year.

General Features

- 1. In 85U+S2X8.5G automatic blow molding machines, the screw diameter is 85 mm and center distance is 80 mm

- 2. It features eight-die head, double station, single layer and high production output.

- 3. Equipped with scissors toggle clamping system, molding clamping is of high rigidity, and the clamping force is extremely large and uniform.

- 4. With high accuracy linear guide rail, this 85U+S2X8.5G is with fast moving speed and stable production.

- 5. Power consumption is decreased due to double-pump and proportion flow valve. Besides, this automatic blow molding machines adopt automatic lubrication system.

- 6. It is configured with thickness control system and auto-scraper.

- 7. It could be optional configured with telemaintenance system;

Technical Data of 85U+S2X8.5G Automatic Blow Molding Machines

1. General Features

| Carriage Horizontal Shuttle Stroke |

mm |

750 |

| Clamp Force |

kN |

94 |

| Air Pressure to Machine |

bar |

6-8 |

| Air Consumption (Estimated) |

m3 / hr |

5 |

| Minimum Pressure for Cooling Water to Machine |

Mpa |

0.2 |

| Power of Pump Motor for Hydraulic Movements |

kW |

11 |

| Power of Servo Pump Motor |

kW |

5.5 |

| Power of Die Head Heating |

kW |

13 |

| Power of Knife |

kW |

2 |

| Total Power Installed (Estimated, Maximum) |

kW |

55.8 |

2. Extruders

| Screw Diameter |

mm |

65 |

45 |

45 |

| Type |

/ |

24 |

24D |

24D |

| Power of Electric Motor |

kW |

15 |

15 |

15 |

| Power of Cooling Fan |

kW |

0.3 |

0.2 |

0.2 |

| Power of Barrel Heating |

kW |

9 |

5.5 |

5.5 |

| Max. Throughput = PE |

kg/h |

60 |

15 |

15 |

| Max. Throughput = PP |

kg/h |

42 |

4.5 |

4.5 |

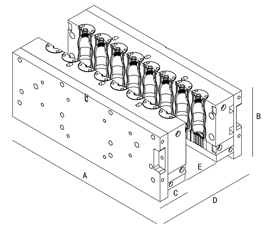

3. Mould Dimensions

| Maximum Width |

A |

mm |

600 |

|

| Maximum Length |

B |

mm |

340 |

| Minimum Depth |

C |

mm |

125 |

| Clamp Open Max. Daylight |

D |

mm |

450 |

| Open Stroke |

E |

mm |

200 |

| Max Weight of Mould |

|

kg |

100 |

4. Production Possibilities

| Cavities |

|

8 |

| Max. Center Distance |

mm |

80 |

| Max. Container Width |

mm |

70 |

| Max. Container Height |

mm |

220 |

| Max. Container Depth |

mm |

135 |

| Container Capacity (Estimated) |

ml |

500 |

5. Machine Dimensions

| Maximum Width |

mm |

4930 |

| Maximum Length |

mm |

4200 |

| Maximum Height |

mm |

2830 |

| Total Weight |

kg |

9000 |

Maintenance for Automatic Blow Molding Machines

We provide one year equipment warranty, free installation for domestic market, for charging debugging in oversea market and all-life services. Equipment parts are free replacement for one year except for the rapid wear parts.

Related Product

English

English Português

Português Français

Français bath toy

bath toy bath toy

bath toy bath-toy

bath-toy christamas ball

christamas ball cleansing

cleansing Medicine

Medicine