75-55U+S2X4.10F 2L Double-Layer Blow Moulding Machine

Description

75-55U+S2X4.10F 2L double-layer blow moulding machine is fully automated with safety lock during high production of bottles for cosmetics, detergents, oil, and so on. It is configured with one to eight mould heads, and its mold frame is designed to traverse on linear motion guides for outstanding performance and high efficiency. Combined with in-mould labeling machines, which can complete the labeling work once the plastic articles come into being, the moulding machine presents less processing procedures when blowing the plastic products. As one of the leading bottle blowing machine makers in China, Lanteky offers you a wide range of blow moulding machines at competitive prices.

| 75-55U+S2X4.10F 2L Double-Layer Blow Moulding Machine | Example | Shampoo Bottle 1000 ml, 70 g |

| Twin Station Blow Moulder up to 2L Double Layer |

Output | 1000/hr, 24000/day, 8.4 million/year |

General Features

- 1. The screw diameter is 75 mm and 55 mm

- 2. 75-55U+S2X4.10F 2L double-layer blow moulding machine is with four mould cavities and double stations. Besides, special screws for material recycle are provided.

- 3. Scissors toggle clamping system contributes to high rigidity mold claming and large clamping force.

- 4. High accuracy linear guide rail greatly increases molding moving speed and ensures stable production.

- 5. With double pump and proportional flow valve, the power consumption is decreased.

- 7. This 2L double-layer blow moulding machine is equipped with automatic lubrication system and thickness control system.

- 8. Touch screen is utilized for easier machine operation. Besides, the intelligent peripheral devices are applied, and the industrial PC networking is available through WIFI or 3G.

- 9. In-mould-labeling is adopted.

- 10. Blow volume ranges from 1 L to 2 L. Available plastic materials are PE, PP, PS, PC, PVC, etc.

Technical Data of 75-55U+S2X4.10F 2L Double-Layer Blow Moulding Machine

1. General Features

| Carriage Horizontal Shuttle Stroke | mm | 650 |

| Dry Cycle | sec | 4.8" |

| Clamp Force | kN | 127 |

Pressure of Hydraulic System |

Mpa | 14 |

Pressure of Pneumatic System |

Mpa | 0.6-0.8 |

Pressure of Cooling System |

Mpa | 0.2-0.3 |

| Air Consumption (Estimated) | m3 / hr | 5 |

| Minimum Pressure for Cooling Water to Machine | Mpa | 0.2 |

| Power of Pump Motor for Hydraulic Movements | kW | 14 |

| Power of Servo Pump Motor (if Needed) | kW | (5.5) |

| Power of Die Head Heating | kW | 6 |

| Power of Knife | kW | 2 |

| Total Power Installed (Estimated, Maximum) | kW | 75.7(84.7) |

2. Extruders

| Screw Diameter | mm | 75/55 |

| Extruder Rotating Speed | / | 20~63/20~40 |

| Power of Electric Motor | kW | 22(30)/11 |

| Power of Barrel Heating | kW | 12.5(13.5)/7.2 |

| Max. Throughput = PE | kg/h | 90(100)/30 |

| Max. Throughput = PP | kg/h | 60 |

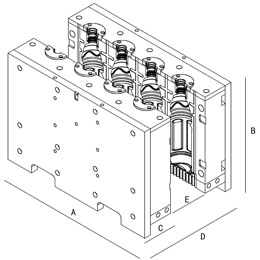

3. Mould Dimensions

| Maximum Width | A | mm | 360 |  |

| Maximum Length | B | mm | 220 | |

| Minimum Depth | C | mm | 200 | |

| Clamp Open Max. Daylight | D | mm | 580 | |

| Open Stroke | E | mm | 350 | |

| Max Weight of Mould | kg | 100 |

4. Production Possibilities

| Cavities | 4 | |

| Max Center Distance | mm | 85/100 |

| Max Container Width | mm | 75/90 |

| Max Container Height | mm | 360 |

| Max Container Depth | mm | 200 |

| Container Capacity (Estimated) | L | 2 |

5. Machine Dimensions

| Maximum Width | mm | 3150/(2200) |

| Maximum Length | mm | 4340 |

| Maximum Height | mm | 2600 |

| Total Weight | kg | 9000 |

Each 2L double-layer blow moulding machine is provided with one year’s warranty. We offer free installation for domestic clients, and all-life services for all clients. During the warranty period, broken machine parts (the fast wear parts excluded) can be replaced into new ones for free.

English

English Português

Português Français

Français