75U+S2X1.10F Extrusion Blow Molding Machine

Introduction

75U+S2X1.10F bottle extrusion blow moulding machine is specialized in producing middle-sized plastic containers like cosmetic bottles, detergent bottles, etc. With double mold bases, one to eight die heads for choice, sliding rail for moving molds, and many other excellent working performances, this machine boasts safe operation and high production efficiency. Besides, a labeling machine is available to co-work with this bottle extrusion blow moulding machine, such as to label the plastic products once after they are formed. In this way, an entire automatic production line cuts down production costs and saves production circle.

| 75U+S2X1.10G | Example | Oil Bottle 5000 ml, 250 g |

| Twin Station Blow Moulder up to 10L | Output | 220/hr, 5400 /day, 1.89 million/year |

General Features of 75U+S2X1.10F Bottle Extrusion Blow Moulding Machine

- 1. The screw diameter is 75 mm.

- 2. Following configurations are optional: single die head, double station, singer layer, double die head, four die head and multi-layer.

- 3. Scissors toggle clamping system enables high rigidity mold clamping. The clamping force is far beyond general claming system.

- 4. 75U+S2X1.10F bottle extrusion blow moulding machine applies high accuracy linear guide rail, ensuring fast moving speed and stable production.

- 5. The double pump and proportional flow valve pull down the power consumption.

- 6. Automatic lubrication system is adopted, and the machine is configured with thickness control system.

- 7. Integration of various take-out concepts makes 75U+S2X1.10F bottle extrusion blow moulding machine more comfortable to operate.

- 8. Modern user-friendly touch screen is designed according to ergonomics and equipped with industrial PC networking. Besides, it supports work through WIFI or 3G.

- 9. Plastic products by this machine are bottles, toys, auto parts, and so on. They are with volume of 5 to 10 liters.

- 10. Available plastic materials processed by 75U+S2X1.10F bottle extrusion blow moulding machine are PE, PP, PS, PC, PVC, etc.

Technical Data of 75U+S2X1.10F Bottle Extrusion Blow Moulding Machine

1. General Features

| Carriage Horizontal Shuttle Stroke | mm | 650 |

| Dry Cycle | sec | 4.8" |

| Clamp Force | kN | 127 |

Pressure of Hydraulic System |

Mpa | 14 |

Pressure of Pneumatic System |

Mpa | 0.6-0.8 |

Pressure of Cooling System |

Mpa | 0.2-0.3 |

| Air Consumption (Estimated) | m3 / hr | 5 |

| Minimum Pressure for Cooling Water to Machine | Mpa | 0.2 |

| Power of Pump Motor for Hydraulic Movements | kW | 14 |

| Power of Servo Pump Motor (if Needed) | kW | (5.5) |

| Power of Die Head Heating | kW | 7 |

| Power of Knife | kW | 2 |

| Total Power Installed (Estimated, Maximum) | kW | 58.5 (67.5) |

2. Extruders

| Screw Diameter | mm | 75 |

| Extruder Rotating Speed | / | 20~60/(20~83) |

| Power of Electric Motor | kW | 22/(30) |

| Power of Barrel Heating | kW | 12.5(13.5) |

| Max. Throughput = PE | kg/h | 120 |

| Max. Throughput = PP | kg/h | 90 |

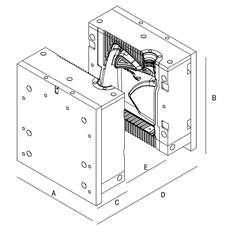

3. Mould Dimensions

| Maximum Width | A | mm | 380 |  |

| Maximum Length | B | mm | 440 | |

| Minimum Depth | C | mm | 115 | |

| Clamp Open Max. Daylight | D | mm | 580 | |

| Open Stroke | E | mm | 230 | |

| Max Weight of Mould | kg | 100 |

4. Production Possibilities

| Cavities | 1 | 2 | 4 | |

| Max. Center Distance | mm | / | 120/200 | 85/100 |

| Max. Container Width | mm | 280 | 110/190 | 75/90 |

| Max. Container Height | mm | 320 | 320 | 320 |

| Max. Container Depth | mm | 190 | 190 | 190 |

| Container Capacity (Estimated) | lt | 10 | 4 | 2 |

5. Machine Dimensions

| Maximum Width | mm | 3150/(2200) |

| Maximum Length | mm | 4340 |

| Maximum Height | mm | 2600 |

| Total Weight | kg | 9000 |

Maintenance for 75U+S2X1.10F Bottle Extrusion Blow Moulding Machine

We provide one year equipment warranty, free installation for domestic market, for charging debugging in oversea market and all-life services. Equipment parts are free replacement for one year except for the rapid wear parts.

We are professional automatic blow molding machine factory and supplier in China. We can produce automatic blow molding machine according to your requirements.

English

English Português

Português Français

Français Bath-Gel

Bath-Gel Dishwa

Dishwa Gear-Oil

Gear-Oil Lubrication Oil

Lubrication Oil Medicine

Medicine Money Savings

Money Savings Oil-Bottle

Oil-Bottle Wide Mouth Jars

Wide Mouth Jars