90Y1 X 1.60D 60L Blow Molding Machine

Introduction

Leshan also manufactures 60L blow moulding machines for chemical barrels. This kind of machine is with one station. Each cavity can blow mould barrel whose volume is up to 60 L. Let bottle which is 50 L and 2500 g be example, this machine can produce 50 bottles each hour, 1200 each day, and 0.42 million per year. We are dedicated high precision bottle blowing machine supplier in China, we can manufacture custom blow molding machines according to clients’ requirements as well.

General Features:

- 1. Accumulator is compound in the main body, which can avoid the explosive fissile convergence line.

- 2. New platform design makes sure that the die head, lifting platform and the head rising are separated from each other. In this way, die head can move more stably.

- 3. With double proportional flow valves, the machine is much evergy-saving.

- 4. This 60L blow moulding machine is configured with down blow pin, down widen device, double clamping system, robot hand and telemaintenance system.

- 5. Air cylinder is adopted instead of oil pump, which gets rid of contamination and loud noise.

- 6. Blowing and mechanical action are divided into three parts, such as to fulfill different atmospheric pressure.

- 7. Strong clamping force makes mold locking tight and fast.

- 8. Lanteky 90Y1 X 1.60D 60L blow moulding machines can be operated automatically or manually.

- 9. Screw diameter is 90 mm.

- 10. Maximum blow volume is 30 L. Available materials are PE, PP, PS, PC and PVC. Products by this machine are chemical barrels, auto parts, sprayers, etc.

Technical Data

1. General Features

| Carriage Horizontal Shuttle Stroke |

mm |

/ |

| Dry Cycle |

sec |

5.8" |

| Clamp Force |

kN |

360 |

| Pressure of Hydraulic System |

Mpa |

14 |

| Pressure of Pneumatic System |

Mpa |

0.6-0.8 |

| Pressure of Cooling System |

Mpa |

0.2-0.3 |

| Air Consumption (Estimated) |

m3 / hr |

5 |

| Minimum Pressure for Cooling Water to Machine |

Mpa |

0.2 |

| Power of Pump Motor for Hydraulic Movements |

kW |

15 |

| Power of Servo Pump Motor (if Needed) |

kW |

(7.5) |

| Power of Die Head Heating |

kW |

22 |

| Power of Knife |

kW |

/ |

| Total Power Installed (Estimated, Maximum) |

kW |

85.5 |

2. Extruders

| Screw Diameter |

mm |

90 |

| Extruder Rotating Speed |

/ |

20~65 |

| Power of Electric Motor |

kW |

37 |

| Power of Barrel Heating |

kW |

17.5 |

| Max. Throughput = PE |

kg/h |

160 |

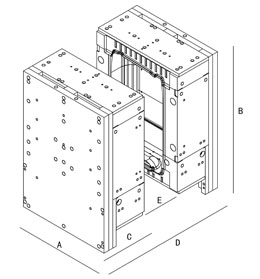

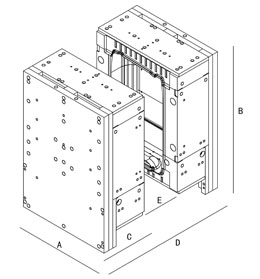

3. Mould Dimensions

| Maximum Width |

A |

mm |

930 |

|

| Maximum Length |

B |

mm |

1270 |

| Minimum Depth |

C |

mm |

225 |

| Clamp Open Max. Daylight |

D |

mm |

1000 |

| Open Stroke |

E |

mm |

550 |

| Max Weight of Mould |

|

kg |

800 |

4. Production Possibilities

| Cavities |

|

1 |

| Max. Center Distance |

mm |

/ |

| Max. Container Width |

mm |

900 |

| Max. Container Height |

mm |

1120 |

| Max. Container Depth |

mm |

390 |

| Container Capacity (Estimated) |

lt |

60 |

5. Machine Dimensions

| Maximum Width |

mm |

2100 |

| Maximum Length |

mm |

5940 |

| Maximum Height |

mm |

3800 |

| Total Weight |

kg |

11500 |

We provide one year equipment warranty for each 90Y1 X 1.60D 60L blow moulding machine. Free installation is offered to domestic users, and the all-life services are to clients all around the world. During the warranty period, damaged equipment parts (excluding quick wear parts) can be changed into new ones for free.

Related Product

English

English Português

Português Français

Français Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic NATF-20-large

NATF-20-large