90Y1X1.30D 30L Blow Molding Machine

Introduction

Leshan 90Y1X1.30D 30L blow molding machines are applicable for moulding plastic bottles containing pesticide, chair, jerry can, water tank and other packing containers which is made from PE, PP, etc. Take 30 L bottle which is 1600 g as example, the machine can produce 45 such kind of bottles per hour, 1080 per day, and 378000 per year. As specialist container blowing devices manufacturer in China, Lanteky provides moulding machines as well as various auxiliary equipments.

General Features:

- 1. 90Y1X1.30D 30L blow molding machines adopt accumulator to avoid the explosive fissile convergence line resulted from parison.

- 2. Die heads, lifts platforms and head-riding are separated from each other, not only making the die head rise more stably, but also can the head move forwards and backwards.

- 3. With the double proportional flow valve, the power consumption is decreased.

- 4. Telemainenance system is optional to clients.

- 5. Air cylinder is employed. Unlike the oil pump, the air cylinder features no contamination and low noise.

- 6. The 30L blow molding machines are configured with automatic lubrication system, down blow pin, down widen device, double clamping, and robot hand.

- 7. Blowing and mechanical action are divided into several parts, thus meeting different atmospheric pressure.

- 8. Clamping force is strong, together with the high pressure and double crank links, making molding locking tight and effectively.

- 9. The screw diameter is 90 mm.

- 10. Maximum blowing volume is 30 L. Available materials are PE, PP, PS, PC and PVC.

- 11. Lanteky 30L blow molding machines can be operated automatically or manually.

Technical Data

1. General Features

| Carriage Horizontal Shuttle Stroke |

mm |

/ |

| Dry Cycle |

sec |

3" |

| Clamp Force |

kN |

450 |

| Pressure of Hydraulic System |

Mpa |

14 |

| Pressure of Pneumatic System |

Mpa |

0.6-0.8 |

| Pressure of Cooling System |

Mpa |

0.2-0.3 |

| Air Consumption (Estimated) |

m3 / hr |

5 |

| Minimum Pressure for Cooling Water to Machine |

Mpa |

0.2 |

| Power of Pump Motor for Hydraulic Movements |

kW |

15 |

| Power of Servo Pump Motor (if Needed) |

kW |

(5.5) |

| Power of Die Head Heating |

kW |

16 |

| Power of Knife |

kW |

/ |

| Total Power Installed (Estimated, Maximum) |

kW |

85.5 |

2. Extruders

| Screw Diameter |

mm |

90 |

| Extruder Rotating Speed |

/ |

20~65 |

| Power of Electric Motor |

kW |

37 |

| Power of Barrel Heating |

kW |

17.5 |

| Max. Throughput = PE |

kg/h |

160 |

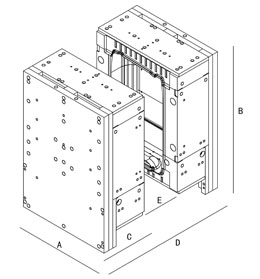

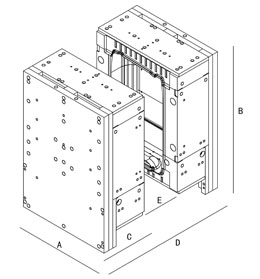

3. Mould Dimensions

| Maximum Width |

A |

mm |

720 |

|

| Maximum Length |

B |

mm |

650 |

| Minimum Depth |

C |

mm |

250 |

| Clamp Open Max. Daylight |

D |

mm |

900 |

| Open Stroke |

E |

mm |

450 |

| Max Weight of Mould |

|

kg |

600 |

4. Production Possibilities

| Cavities |

|

1 |

| Max. Center Distance |

mm |

/ |

| Max. Container Width |

mm |

700 |

| Max. Container Height |

mm |

500 |

| Max. Container Depth |

mm |

340 |

| Container Capacity (Estimated) |

lt |

30 |

5. Machine Dimensions

| Maximum Width |

mm |

2830 |

| Maximum Length |

mm |

4900 |

| Maximum Height |

mm |

3500 |

| Total Weight |

kg |

9250 |

We provide one year equipment warranty for our 90Y1X1.30D 30L blow molding machines. Besides, free installation is offered for domestic market. All-life service is provided to clients all over the world. Equipment parts are free replacement for one year except for the rapid wear parts.

Related Product

English

English Português

Português Français

Français Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic NATF-20-large

NATF-20-large