30L Extrusion Blow Molding Machine

Introduction

This extrusion blowing molding machinery is designed for engineering part, with max blow volume of 30L, and out put of 45/hr, 1100 /day. Such bottle made from plastic resin of PP, PVC, PE, PC, PS is applicable for this machine.

Model: 90H1x1.30D For Engineering parts

Brief Introduction of 30L Extrusion Blowing Molding Machinery

| 90H1x1.30D For Engineering parts |

Example |

bottle 20L, 1200g |

| One station, one cavity blow moulder up to 30L |

Output |

45/hr, 1100 /day, 0.38million/year |

General Features:

Specification:

-

1. The machine is with new platform design for the die head, which separates the lifting platform from head-rising platform, not only making the lifting and rising of the die head more stable, but also making the die head more easy to move forwards and backwards;

- 2. The main body is equipped with accumulator to avoid the explosive fissile convergence line that caused by parision combined in the material-storage-on-top accumulator;

- 3. Equipped with the double pump, proportion flow valve, the power consumption can be reduced effectively;

- 4. This 30L extrusion blowing molding machinery has automatic lubrication system, and robot hand, down widen device, down blow pin, double clamping also;

- 5. It could be optional configured with tele-maintenance system;

- 6. It’s driven by the air cylinder instead of the oil pump, with low noise and zero contamination

- 7. Double crank links to lock the mold & Strong clamping force;

- 8. Automatic and manual operation;

- 9. Different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

- 10. With unique design of the valve position, which is reliable and safe, the air pressure diagram of the machine can be easy to understand;

- 11. The screw diameter is 90mm;

- 12. Applicable materials: PP, PVC, PE, PC, PS; the max blow volume: 30L;

- 13. Our machine can be used in making of auto parts, chemical barrels, pesticide sprayer and so on.

Technical Data

1. General Features

| Carriage horizontal shuttle stroke |

mm |

/ |

| Dry cycle |

sec |

3" |

| Clamp force |

kN |

450 |

| Pressure of Hydraulic System |

Mpa |

14 |

| Pressure of Pneumatic System |

Mpa |

0.6-0.8 |

| Pressure of Cooling System |

Mpa |

0.2-0.3 |

| Air consumption (estimated) |

M3 / hr |

5 |

| Minimum pressure for cooling water to machine |

Mpa |

0.2 |

| Power of pump motor for hydraulic movements |

kW |

15 |

| Power of servo pump motor(if needed) |

kW |

(5.5) |

| power of Die head heating |

kW |

16 |

| Power of knife |

kW |

/ |

| Total power installed (estimated, maximum) |

kW |

85.5 |

2. Extruders

| Screw diameter |

mm |

90 |

| Extruder rotating speed |

/ |

20~65 |

| Power of electric motor |

kW |

37 |

| Power of barrel heating |

kW |

17.5 |

| Max throughput = PE |

kg/h |

160 |

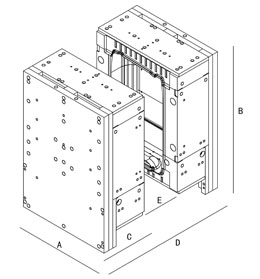

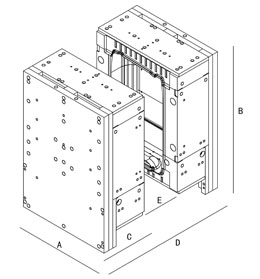

3. Mould Dimensions

| Maximum Width |

A |

mm |

700 |

|

| Maximum Length |

B |

mm |

650 |

| Minimum Depth |

C |

mm |

250 |

| Clamp Open Max. Daylight |

D |

mm |

900 |

| Open Stroke |

E |

mm |

450 |

| Max Weight of Mould |

|

kg |

600 |

4. Production Possibilities

| Cavities |

|

1 |

| Max center distance |

mm |

/ |

| Max container width |

mm |

700 |

| Max container height |

mm |

500 |

| Max container depth |

mm |

340 |

| Container capacity (estimated) |

lt |

30 |

5. Machine Dimensions

| Maximum width |

mm |

2830 |

| Maximum length |

mm |

4900 |

| Maximum height |

mm |

3500 |

| Total weight |

kg |

9250 |

We provide our costums one year warranty for the 30L extrusion blowing molding machinery, free installation for domestic market, charging for debugging in international market and lifetime services. The replacement of 30L extrusion blowing molding machinery parts is one year for free, expect the rapid wear parts.

Related Product

English

English Português

Português Français

Français Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic NATF-20-large

NATF-20-large