100L Blow Molding Machine

Introduction

100H+S1X1.100D 100L blow molding machines are specialized in production of chemical barrels whose maximum volume is 100 L. Take 50 L tanks as example, this machine can produce 50 these bottles in each hour, 1200 per day, and 0.42 million per year. Apart from being barrel blowing machinery maker, we are also specialist manufacturer of moulding machines for middle sized and small sized plastic bottles.

General Features:

- 1. 100H+S1X1.100D 100L blow molding machines are equipped with accumulator inside to avoid the explosive fissile convergence line.

- 2. The die head, lifting platform and head rising are separated from each other, not only making the die rising more stable, but also letting the die head move forwards and backwards.

- 3. Double-pump proportional valve makes the power consumption greatly decreased.

- 4. Air cylinder is applied to avoid contamination and damp the noise.

- 5. 100H+S1X1.100D 100L blow molding machines are configured with automatic lubrication system, blow pins, down widen devices, double clamping systems, robot hands and telemaintenance system.

- 6. Blowing and mechanical action are separated into three parts, meeting different requirements on atmospheric pressures.

- 7. It is of strong clamping force.

- 8. This 100L blow molding machine can be operated in automatic and manual way.

- 9. Valve is safely and reliably designed.

- 10. Screw diameter is 100 mm.

- 11. Maximum blow volume is 100L.

- 12. Available materials are PE, PP, PS, PC and PVC.

Technical Data

1. General Features

| Carriage Horizontal Shuttle Stroke |

mm |

/ |

| Dry Cycle |

sec |

6" |

| Clamp Force |

kN |

800 |

| Pressure of Hydraulic System |

Mpa |

14 |

| Pressure of Pneumatic System |

Mpa |

0.6-0.8 |

| Pressure of Cooling System |

Mpa |

0.2-0.3 |

| Air Consumption (Estimated) |

m3 / hr |

5 |

| Minimum Pressure for Cooling Water to Machine |

Mpa |

0.2 |

| Power of Pump Motor for Hydraulic Movements |

kW |

15 |

| Power of Servo Pump Motor (if Needed) |

kW |

(11) |

| Power of Die Head Heating |

kW |

35 |

| Power of Knife |

kW |

/ |

| Total Power Installed (Estimated, Maximum) |

kW |

158/(181) |

2. Extruders

| Screw Diameter |

mm |

100 |

| Extruder Rotating Speed |

/ |

20~71 |

| Power of Electric Motor |

kW |

55/(75) |

| Power of Barrel Heating |

kW |

27/(30) |

| Max. Throughput = PE |

kg/h |

180/(230) |

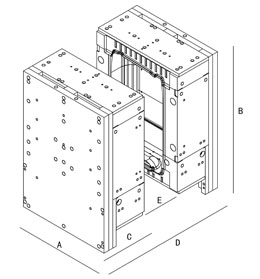

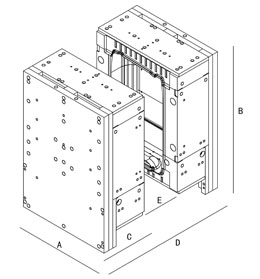

3. Mould Dimensions

| Maximum Width |

A |

mm |

1150 |

|

| Maximum Length |

B |

mm |

1450 |

| Minimum Depth |

C |

mm |

400 |

| Clamp Open Max. Daylight |

D |

mm |

1600 |

| Open Stroke |

E |

mm |

800 |

| Max Weight of Mould |

|

kg |

800 |

4. Production Possibilities

| Cavities |

|

1 |

| Max. Center Distance |

mm |

/ |

| Max. Container Width |

mm |

1100 |

| Max. Container Height |

mm |

1300 |

| Max. Container Depth |

mm |

690 |

| Container Capacity (Estimated) |

lt |

100 |

5. Machine Dimensions

| Maximum Width |

mm |

5200 |

| Maximum Length |

mm |

5300 |

| Maximum Height |

mm |

6700 |

| Total Weight |

kg |

31000 |

We provide one year equipment warranty, free installation for domestic market, all-life services for all clients around the world. Equipment parts of 100H+S1X1.100D 100L blow molding machines share free replacement for one year except for the rapid wear parts.

Related Product

English

English Português

Português Français

Français Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic Blowing Plastic

Blowing Plastic NATF-20-large

NATF-20-large