Product » Blow Moulding Machine » PET Stretch Blow Molding Machine » EPET06-4H Stretch Blow Molding Machine

EPET06-4H Stretch Blow Molding Machine

Features:

- 1. EPET06-4H stretch blow moulding machine adopts energy saving servo control that not only could accomplish high-speed mold open & close but also save 30% energy compare to the machines manufactured by other PET bottle molding machinery suppliers.

- 2. The mold clamping plate adopts the special design of three-plates self-locking that could clamp fast at first then get slow mutely, meeting the demand of the increasing clamping force.

- 3. The heating box structure is designed at 6 adjusted zones. It fulfills different heating requirements for different length of tube.

- 4. This stretch blow moulding machine features stable pneumatic system, smooth buffering performance and low noise.

- 5. It is controlled by all electric servo motor, avoiding the hydraulic oil leakage and contamination.

- 6. It is with four cavities. The maximum blow volume is 0.6 L.

- 7. These machines have a unique design according to the effect on the PET material. Multiple blowing steps reduce PET residual stress.

- 8. Hot fill PET bottles are able to stand high temperatures ranging from 82°C to 95°C without deformation. This is an incredible success in the hot fill beverage domain.

- 9. EPET06-4H stretch blow moulding machine is operated by user-friendly PLC system.

- 10. Preform positioning is conducted by servo-motor technology.

- 11. It is en ideal solutions for medium output production needs.

Technical Specifications

| Molding Specification | Output (Basic on 0.6 L Bottle) | bph | 5800 |

| Clamping Force | kN | 480 | |

| Max. Mold Stroke | mm | 100 | |

| Mold Thickness | mm | 180 | |

| Max. Mold Size (H × W) | mm | 320 × 312 | |

| Stretching Stroke | mm | 340 | |

| Bottom Stroke | mm | 50 | |

| Cavity Distance | mm | 76.2 | |

| Number of Cavities | / | 4 | |

| Bottle Specification | Max. Bottle Capacity | L | 0.6 |

| Neck Diameter Range | mm | 18-35 | |

| Bottle Diameter | mm | 68 | |

| Bottle Height | mm | 240 | |

| Electrisify Specification | Heating Power | kW | 32 |

| Preform Feeding Motor | kW | 0.25 | |

| Rotating Motor | kW | 0.12 | |

| Revolution Motor | kW | 1.5 | |

| Clamping Motor | kW | 3 | |

| Total Power | kW | 37 | |

| Actual Power Consumption | kW | ≤20 | |

| Air Compressor Specification (Basic on 0.6 L Bottle) |

Operating Pressure | Mpa | 0.7 |

| Low Pressure Air Consumption | m3/min | 1.5 | |

| Blowing Pressure | Mpa | 3.5 | |

| Hight Pressure Air Consumption | m3/min | 4.5 | |

| Chiller Specification | Operating Pressure | kg/cm2 | 5 |

| Temperature Range | ℃ | 25 | |

| Heat Consumption | kcal/hr | 40000 | |

| Flow Rate | L/min | 150 | |

| Machine Specification | Size (L × W× H) | m | 3.8 × 2.15 × 2.5 |

| Weight | kg | 5200 | |

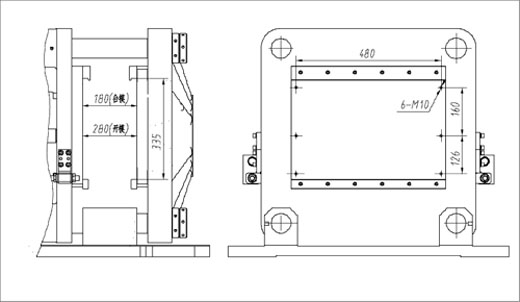

| Mould Plate (mm) |  |

||

Related Product

English

English Português

Português Français

Français PET

PET PET

PET PET

PET PET

PET PET

PET PET

PET PET

PET PET

PET PET

PET PET

PET PET

PET PET

PET