65K+S2X1.5F 5L Detergent Bottle Extrusion Blow Molding Machine

Introduction

65K+S2X1.5F 5L detergent bottle extrusion blow molding machines are equipped with two stations and two mould cavities. It can form plastic article whose maximum volume is 5 L. This machine can produce 500 detergent bottles (each is 1 L and 65 g) per hour and 12000 per day. Apart from this, multi-cavity type is optional.

General Features

- 1. The screw diameter is 65 mm.

- 2. Up to six die heads are optional for clients.

- 3. This detergent bottle extrusion blow molding machine applies Siemens PLC system and human-machine interface to serve for the electric system.

- 4. Lanteky adopts Yuken hydraulic valves and pumps for machines’ hydraulic system.

- 5. Plasticizing system is of high efficiency and low energy consumption.

- 6. In parison injection, the single hydraulic cylinder works without non-synchronization.

- 7. Invertor and harden surface gear box are employed in its extruding system.

- 8. In the detergent bottle extrusion blow molding machine, the extruding cover is adjustable upwards and downwards. The mould head is moved by hydraulic force, and molding changing is convenient.

- 9. Clamping system is designed into center locking clamping mechanism. Hence, long-term clamping force balance is guaranteed.

Technical Data of 65K+S2X1.5F 5L Detergent Bottle Extrusion Blow Molding Machine

1. General Features

| Carriage Horizontal Shuttle Stroke | mm | 450 |

| Dry Cycle | sec | 8” |

| Clamp Force | kN | 50 |

Pressure of Hydraulic System |

Mpa |

16 |

Pressure of Pneumatic System |

Mpa |

0.6-0.8 |

Pressure of Cooling System |

Mpa |

0.2-0.3 |

| Air Consumption (Estimated) | m3 / hr | 5 |

| Minimum Pressure for Cooling Water to Machine | Mpa | 0.2 |

| Power of Pump Motor for Hydraulic Movements | kW | 7.5 |

| Power of Servo Pump Motor (if Needed) | kW | (5.5) |

| Power of Die Head Heating | kW | 5 |

| Power of Knife | kW | 2 |

| Total Power Installed (Estimated, Maximum) | kW | 38.5(44) |

2. Extruders

| Screw Diameter | mm | 65 |

| Extruder Rotating Speed | / | 20~67 |

| Power of Electric Motor | kW | 7.5 |

| Power of Barrel Heating | kW | 9 |

| Max. Throughput = PE | kg/h | 60 |

| Max. Throughput = PP | kg/h | 42 |

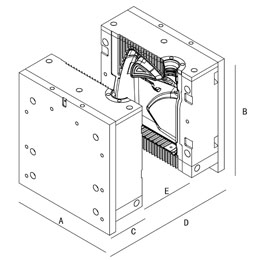

3. Mould Dimensions

| Maximum Width | A | mm | 300 |  |

| Maximum Length | B | mm | 375 | |

| Minimum Depth | C | mm | 100 | |

| Clamp Open Max. Daylight | D | mm | 450 | |

| Open Stroke | E | mm | 200 | |

| Max Weight of Mould | kg | 100 |

4. Production Possibilities

| Cavities | 1 | 2 | 4 | |

| Max. Center Distance | mm | / | 120/160/170/200 | 65/70/75/85/100 |

| Max. Container Width | mm | 280 | 110/150/160/190 | 55/60/65/75/90 |

| Max. Container Height | mm | 105 | 105 | 105 |

| Max. Container Depth | mm | 160 | 160 | 160 |

| Container Capacity (Estimated) |

L | 5 | 1.5 | 1 |

5. Machine Dimensions

| Maximum Width | mm | 2100 |

| Maximum Length | mm | 3400 |

| Maximum Height | mm | 2200 |

| Total Weight | kg | 4600 |

We provide one year equipment warranty to each 65K+S2X1.5F 5L detergent bottle extrusion blow molding machine. Besides, free installation is provided to domestic clients, and all-life services to clients around the world. Equipment parts, except for the rapid wear parts, share free replacement if they are damaged during warranty period.

English

English Português

Português Français

Français oil bottle

oil bottle wide_mouth_jars

wide_mouth_jars Cleaning products

Cleaning products