45YG2X1.1C PVC Extrusion Blow Moulding Machine

Introduction

45YG2X1.1C PVC extrusion blow moulding machine is used to produce plastic bottles with materials like PETG, PVC, and so on. It is equipped with one or two mould cavities, specialized in forming small packing articles for containing medicine, cosmetic, pesticide, etc. As one of China’s most reliable plastic blowing device manufacturers, Lanteky offers you a wide range of products which feature compact structure, low energy consumption, high production output, great working performance and user-friendliness. All component parts of 45YG2X1.1C PVC extrusion blow moulding machine are produced by CNC machine in order to maintain high precision.

Brief Introduction

| 45YG2X1.1C |

Example |

Bottle 1 L, 70 g |

| Twin station two cavities blow moulder up to 0.05L |

Output |

300/hr, 7200/day, 2.5million/year |

General Features:

-

1. High-rigidity double die heads and stations are provided.

- 2. There are three bar horizontal stations.

- 3. Bottles produced by this PVC extrusion blow moulding machine mainly are single-layer articles.

- 4. Screw is controlled by the inverter.

- 5. It can be optionally configured with thickness control system and auto-deflasher device.

- 6. This series PVC extrusion blow moulding machines are of simple appearance and compact structure. The dry cycle time is only 3 seconds.

- 7. Screw diameter is 45 mm.

- 8. For this machine, the maximum blow volume is 1 L. Apart from PVC and PETG, other available materials are PE, PP, PS, PC, etc.

Technical Data of 45YG2X1.1C PVC Extrusion Blow Moulding Machine

1. General Features

| Carriage Horizontal Shuttle Stroke |

mm |

314 |

| Dry Cycle |

sec |

3" |

| Clamp Force |

kN |

17 |

| Pressure of Hydraulic System |

Mpa |

14 |

| Pressure of Pneumatic System |

Mpa |

0.6-0.8 |

| Pressure of Cooling System |

Mpa |

0.2-0.3 |

| Air Consumption (Estimated) |

m3 / hr |

3 |

| Minimum Pressure for Cooling Water to Machine |

Mpa |

0.2 |

| Power of Pump Motor for Hydraulic Movements |

kW |

4 |

| Power of Servo Pump Motor(If Needed) |

kW |

(5.5) |

| Power of Die Head Heating |

kW |

3.2 |

| Power of Knife |

kW |

2 |

| Total Power Installed (Estimated, Maximum) |

kW |

21.2 |

2. Extruders

| Screw Diameter |

mm |

45 |

| Extruder Rotating Speed |

/ |

20~60 |

| Power of Electric Motor |

kW |

7.5 |

| Power of Barrel Heating |

kW |

4.5 |

| Max. Throughput = PVC |

kg/h |

20 |

| |

|

|

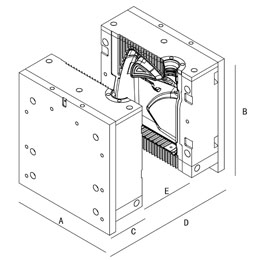

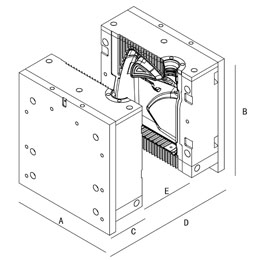

3. Mould Dimensions

| Maximum Width |

A |

mm |

230 |

|

| Maximum Length |

B |

mm |

280 |

| Minimum Depth |

C |

mm |

50 |

| Clamp Open Max. Daylight |

D |

mm |

150 |

| Open Stroke |

E |

mm |

75 |

| Max Weight of Mould |

|

kg |

100 |

4. Production Possibilities

| Cavities |

|

1 |

2 |

|

|

| Max. Center Distance |

mm |

/ |

70/85 |

|

|

| Max. Container Width |

mm |

230 |

60/75 |

|

|

| Max. Container Height |

mm |

280 |

160 |

|

|

| Max. Container Depth |

mm |

37.5 |

25 |

|

|

| Container Capacity (Estimated) |

lt |

1 |

0.5 |

|

|

5. Machine Dimensions

| Maximum Width |

mm |

1750 |

| Maximum Length |

mm |

2400 |

| Maximum Height |

mm |

2100 |

| Total Weight |

kg |

2200 |

Equipment warranty for each PVC extrusion blow moulding machine is one year, during which you can ask for machine part replacement service for free if it is damaged (the quick wear parts are excluded). Besides, we offer free installation service to domestic clients and all-life service for our clients around the world.

Related Product

English

English Português

Português Français

Français