PETG and PVC Blow Molding Machine

Introduction

PETG, Polyethylene terephthalate (PET, PETE) is a plastic resin of the polyester family that is used to make beverage, food and other liquid bottles or containers, as well as for some other thermoforming applications.

Polyvinyl chloride (PVC) is a popular vinyl based material that is used in container making applications. It has a high strength to weight ratio, is weather resistant, and offers great chemical resistance.

This blowing molding machine is specially designed for thermoforming those 0.05L, 8g lucid containers that made from PETG, PVC material with out put 1200/hr, 28000 /day.

Model:55Y2X2.05D (PETG Series)

Brief Introduction

| 55Y2X2.05D (PETG Series) |

Example |

bottle 0.05L, 8g |

| Twin station two cavities blow moulder up to 0.05L |

Output |

1200/hr, 28000 /day, 8.4million/year |

General Features:

Specification of this Blow Molding Machine:

-

1. Single layer, double die head and double station;

- 2. 3 tie bar horizontal station

- 3. PVC screw and PVC die head with high rigidity;

- 4. The screw is controlled by inverter; screw diameter is 55mm;

- 5. This series of machine is of compact design, and robust construction; only 3 seconds cycle time;

- 6. This blowing molding machine can be optional configured with auto-deflasher and device thickness control system;

- 7. Applicable materials: PVC, PC, PETG, PS; the max blow volume: 0.5L;

- 8. This blowing molding machine can be used in making of medical containers, bottle caps, cosmetic bottles, shampoo bottles and other such products.

Technical Data

1. General Features

| Carriage horizontal shuttle stroke |

mm |

300 |

| Clamp force |

kN |

17 |

| Dry cycle |

sec |

3" |

| Pressure of Cooling System |

Mpa |

0.2-0.3 |

| Pressure of Pneumatic System |

Mpa |

0.6-0.8 |

| Pressure of Hydraulic System |

Mpa |

14 |

| Air consumption (estimated) |

M3 / hr |

3 |

| Minimum pressure for cooling water to machine |

Mpa |

0.2 |

| Power of knife |

kW |

2 |

| power of Die head heating |

kW |

3 |

| Power of servo pump motor(if needed) |

kW |

(5.5) |

| Power of pump motor for hydraulic movements |

kW |

4 |

| Total power installed (estimated, maximum) |

kW |

22.3 |

2. Extruders

| Screw diameter |

mm |

55 |

| Extruder rotating speed |

/ |

20~60 |

| Power of barrel heating |

kW |

7.3 |

| Power of electric motor |

kW |

11 |

| Max throughput = PETG |

kg/h |

20 |

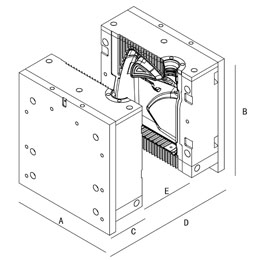

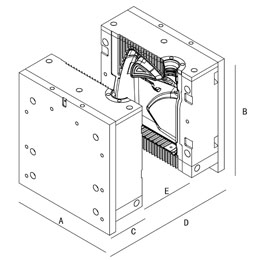

3. Mould Dimensions

| Maximum Width |

A |

mm |

230 |

|

| Maximum Length |

B |

mm |

280 |

| Minimum Depth |

C |

mm |

50 |

| Clamp Open Max. Daylight |

D |

mm |

150 |

| Open Stroke |

E |

mm |

75 |

| Max Weight of Mould |

|

kg |

100 |

4. Production Possibilities

| Cavities |

|

2 |

| Max center distance |

mm |

85 |

| Max container width |

mm |

230 |

| Max container height |

mm |

280 |

| Max container depth |

mm |

37.5 |

| Container capacity (estimated) |

lt |

0.5 |

5. Machine Dimensions

| Maximum width |

mm |

1990(1750) |

| Maximum length |

mm |

2390 |

| Maximum height |

mm |

2050 |

| Total weight |

kg |

2000 |

We provide our costumes with one year warranty for the blowing molding machine, free installation for domestic market, charging for debugging in international market and lifetime services. The replacement of machine parts is one year for free, expect the rapid wear parts.

Related Product

English

English Português

Português Français

Français