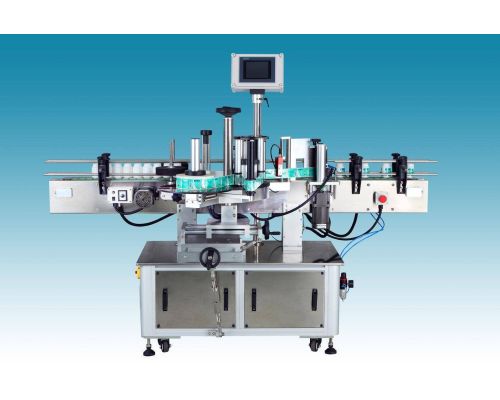

Description:

The automatic vertical labeling machine is specially designed for full or partial wrap around round containers at different sizes. It can at most label 150 containers per minute In light of the performance. Meanwhile, the equipment of roller spacing device makes no change parts required.

Operation of the Vertical Labeling Machine

The round containers positioned on the conveyor are first released at the equal distance with the help of the roller spacing device. At the labeling point, an electronic device will sense the coming container and release correspondingly a label from self adhesive label roll which the container will pick as it moves on conveyor. The labeled container then moves further through a rubber pressing belt and stationary rubber which ensures neat and perfect fixing of label on the container diameter. If the vertical labeling machine is equipped with batch printing device (optional), batch printing device will print the batch number and other contents on label when the label is stationary between distributions of the two labels.

Salient Features of Vertical Labeling Machine:

- 1. Stainless Steel cladding or hard chrome plating of all exposed parts ensure long life and resistance against corrosion.

- 2. Adjustable conveyor height to align with other machine of the line.

- 3. Minimum changeover time is required from one size of container or label to another.

- 4. Special self-aligning bearings ensure smooth and trouble free rotation of the parts and contribute to quick assemble during periodical maintenance of the unit. They also allow more flexibility in maintaining tolerances.

- 5. The electrical sensing device of the vertical labeling machine avoids wastage of labels and helps in keeping the unit neat and clean.

- 6. Suitable for overlap labeling and flag type labeling when the length of label is more than circumference of the container.

- 7. A highly efficient vacuum pump releases sufficient vacuum to hold labels big or small on the pick-up cylinder.

- 8. Complete protection of the motors is ensured by the contactors and relays of appropriate ratings.

English

English Português

Português Français

Français